Build with Confidence

Follow the Project

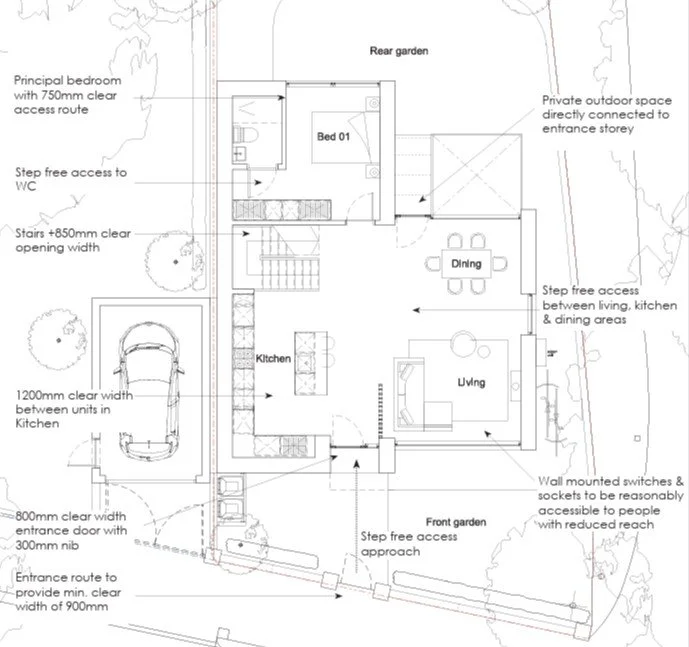

This contemporary new-build home replaces a tired bungalow with a carefully designed, energy-efficient family dwelling. Set within a conservation area near Wandsworth Common, the project champions sustainable design, accessibility, and low-impact living, featuring reclaimed brickwork, natural timber cladding, and a zinc roof.

Follow the journey as this future-ready home takes shape.

We’re taking a traditional procurement route for The Eco House, with a clearly defined scope and coordinated design responsibility across a full professional team. A main contractor has been appointed and is, working alongside an experienced design team that includes the architect, structural and civil engineers, M&E consultants, a health and safety advisor, and a cost consultant.

All of these professionals are accessible to those following the Plan It or Build It pathways inside the Homebuilding Essentials platform.

To manage risk and cost, the project is split into distinct packages. First, we are competitively tendering the basement works to three specialist contractors. This includes piling, reinforced concrete walls, waterproofing, and ground slab construction.

Once the basement is complete, we’ll hand over to a pre-selected supply-and-install timber frame contractor for the superstructure. The main contractor will then resume works for the external envelope, including reclaimed yellow stock brickwork, vertical timber cladding, and a pre-weathered zinc roof.

Some elements of the build such as the timber frame and windows, are specified as named suppliers by the design team. This means particular products or systems are required to meet the design intent, performance targets, or aesthetic goals, and are included in the specification from the outset.

We are now preparing a cost plan to establish a baseline budget using current market rates. This will help guide both the client and the design team on financial expectations. A version of this same plan, stripped of pricing, will be issued to subcontractors and suppliers to ensure their works packages are based on a consistent set of information and specification details.

Project Structuring - Procurement Strategy & Delivery Route

We’re delivering The Eco House using a traditional procurement route, supported by a full professional team including architect, engineers, M&E, health & safety, and cost consultants. A main contractor is appointed for the full build, with early packages such as the basement works, being competitively tendered to specialists.

A supply-and-fit timber frame contractor has been secured for the superstructure, and the main contractor will then complete the envelope and internal fit-out. A full cost plan is being developed to guide budgets and tender returns, helping ensure quality and cost control from the outset.

July 25. Site Setup & Asbestos Removal Preparation

The project has entered a critical phase of site preparation, covering temporary infrastructure, safety measures, and ecological responsibilities. Asbestos removal is being carefully planned and managed in line with HSE regulations, a vital step before demolition begins.

We’re now preparing the site for works to commence. This includes applying for a temporary pavement crossover licence, disconnecting utilities from the property, and establishing temporary services (power and water) at the site boundary. Perimeter hoarding will soon be installed to secure the site and ensure public safety.

As part of our ecological and planning commitments, we’re also installing tree root protection measures and clearing vegetation. An asbestos survey identified high-risk materials within the existing bungalow. As a result, we’ve appointed a licensed asbestos removal contractor. In line with Health and Safety Executive (HSE) requirements, we’ve submitted formal notification and detailed method statements, allowing for a mandatory 10-day notification period.

During removal, the building will be fully scaffolded, wrapped in monoflex, and enclosed within an air-monitored containment zone. Once the asbestos is safely removed, demolition of the bungalow can proceed.

July 25. Asbestos Removal

The project has entered a critical phase of site preparation, covering temporary infrastructure, safety measures, and ecological responsibilities. Asbestos removal is being carefully planned and managed in line with HSE regulations, a vital step before demolition begins.

Following the required 14-day notification to the Health and Safety Executive (HSE), we mobilised on-site as planned and in line with the project programme. The asbestos-containing materials identified in the pre-demolition survey included external soffits and fascias, which necessitated full enclosure. In accordance with the Control of Asbestos Regulations 2012, a licensed contractor was appointed to undertake the works, ensuring all procedures followed strict legal and environmental protocols.

A purpose-built enclosure was constructed to fully wrap the bungalow below the roofline, maintaining negative pressure within the work zone throughout the removal process. Air monitoring was carried out continuously, and a dedicated decontamination unit was installed on-site to manage personnel movements safely. Viewing panels were set up to allow safe observation of the removal process (where two of these photos are taken from) while a clearly defined waste route ensured all contaminated material was double-bagged and disposed of in line with hazardous waste regulations.

This setup demonstrates the correct approach to licensed asbestos removal, controlled, monitored, and fully compliant.

July 25. Demolition – Notice, Certification & Coordination

With asbestos safely removed and the site now ready, we’ve progressed into the demolition phase — a pivotal stage in the programme that requires detailed preparation well ahead of any machine arriving on site.

In line with statutory requirements, a demolition notice was submitted to the local authority six weeks in advance. These notices are a legal requirement and must be supported by a range of documentation, including evidence of utility disconnections, statements of intent, and confirmation of liaison with the relevant service providers. It’s important to note that incoming demolition contractors will require written confirmation of utility disconnections, certificates from the network providers, before taking possession of the site.

While awaiting formal response from the council (which, under the legislation, allows works to proceed after six weeks if no reply is received), we continued coordinating several key parallel tasks behind the scenes. These activities (all of which are unpacked inside the Plan It learning pathway) include progressing the cost plan alongside design development, liaising with the council regarding the temporary crossover licence, and ensuring the certified sign-off from the asbestos removal contractor is received and documented in time for issue to the demolition contractor.

Although we had technically met the six-week threshold without formal objection, we took a diligent step further and contacted the council directly by phone to obtain verbal clearance. This provided peace of mind and avoided any potential risk of a procedural dispute during demolition.

With approval confirmed, the demolition contractor, who had already begun setting up perimeter hoarding and safety signage was given the go-ahead to commence. Simultaneously, we’ve been in active dialogue with the basement and piling specialists and our cost consultant. These conversations cover all critical pre-start items, including:

Lead times and mobilisation planning

Welfare provision expectations

Site access and logistics strategy

Payment terms and contract admin

Programme commitments and delay clauses

All of this is about managing risk early and ensuring a seamless handover between demolition and the specialist works to follow.

Aug 25. Breaking Ground - Piling Contractor Start

With demolition underway, our focus now shifts to preparing the site for piling and excavation. Before the specialist contractor can begin, the site must be fully cleared — and that includes what lies beneath the surface.

It’s not enough to remove just the above-ground structure. The existing foundations, legacy drainage, and any redundant underground services must also be grubbed out to create a clean, obstruction-free footprint for the new basement. This is critical to avoid unforeseen delays and costs.

Ahead of mobilisation, the demolition contractor will mark out the line of the new building footprint and carry out ground probing to a depth of at least 1.5 metres along the proposed piling zone. This helps confirm the ground is free from significant obstructions. If obstacles are discovered during piling works, these may result in delays, variations, and additional cost — which is why a clear and verified site handover is essential.

All of this forms part of a carefully phased transition from demolition to groundworks — a principle covered in detail inside the Build It pathway of Homebuilding Essentials.